Home » Our industrial tool

Our industrial tool

Two certified industrial sites are dedicated to the manufacture and packaging of your products : in Brittany and in Rhône-Alpes. Equipped with state-of-the-art facilities, in working conditions adapted to the processing of dry and liquid forms, our factories are divided into manufacturing cells for each machine to guarantee product safety.

Weighing units

6 weighing units

Recipes are weighed on weighing stations linked to the ERP, which allow operational conformity to be validated in real time.

Powder-blending equipment

3 powder blenders

Powders are mixed in tanks of different capacities which directly feed the manufacturing machines.

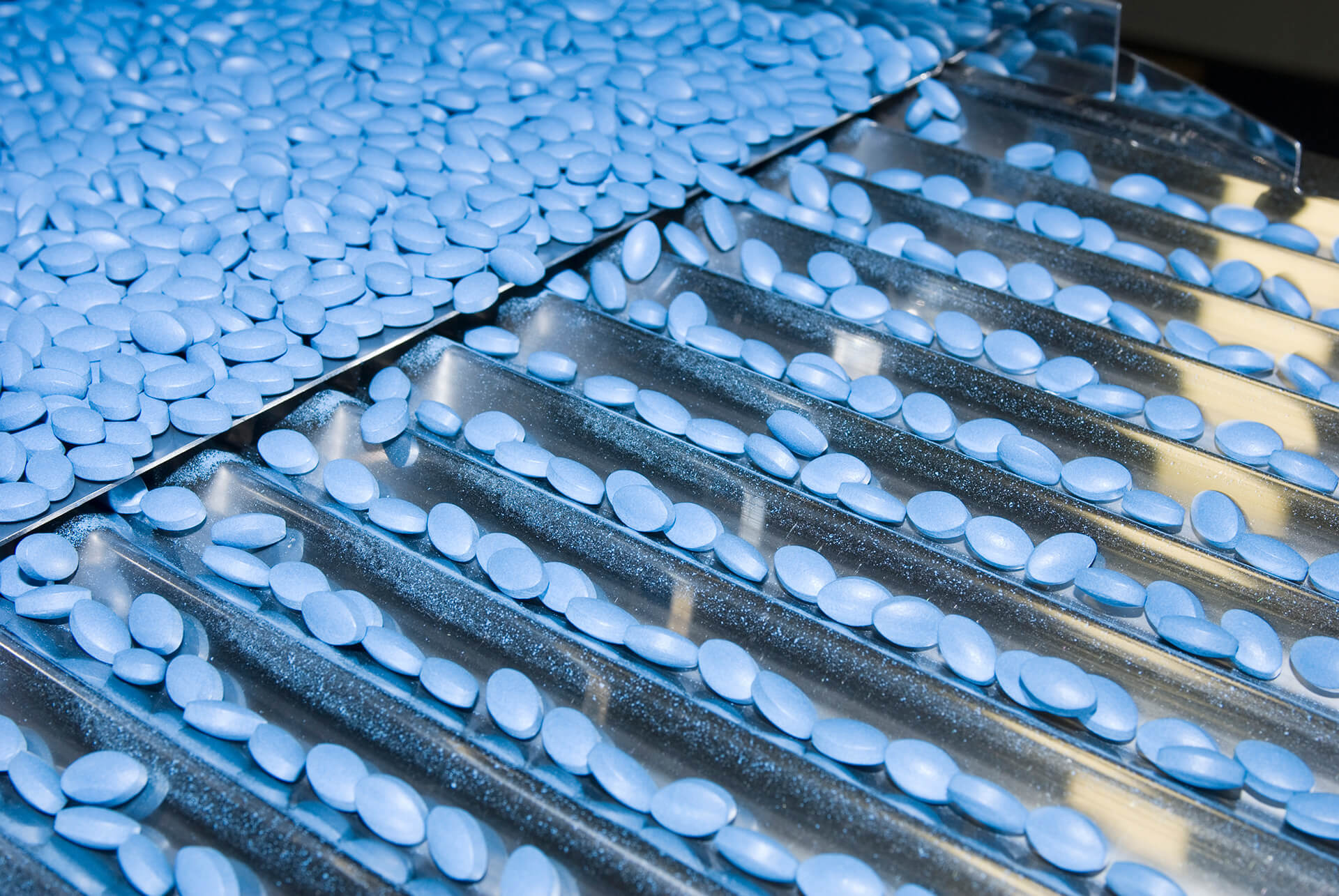

Tablet presses

7 tablet presses

Our varied range of tablet presses means we can produce the most complex products, with capacities between 40,000 and 100,000 tablets/hour.

Capsule-filling machines

6 capsule-filling machines

The capsule-filling machines chosen for their high reliability and flexibility have speeds of 40,000 or 80,000 capsules/hour.

Coating and sugar-coating machines

5 sugar-coating machines

The various machines adapt to batch sizes, from 40 kg to 400 kg per batch. One coating machine is equipped to produce sugar-coated tablets.

Sachet-packaging machines

3 sachet-packaging machines

The sachet-packaging machines, with a rate of 4,000 sachets/hour, can make single sachets or dual-pocket sachets, in bulk or placed in a carton on the line.

Stick-pack packaging machines

1 stick filler

The powder stick filler is equipped with 4 lanes, with a rate of 6,000 sticks/hour.

Liquid-filling machines

2 liquid fillers

Liquid fillers specialise in small capacities (5–200 ml) and larger-volume bottles (100–500 ml).

Blister-packaging machines

3 blister-packaging machines

The 3 blister packaging machines with a rate of 60 strokes/minute are equipped with automatic cartoners with insertion of leaflets.

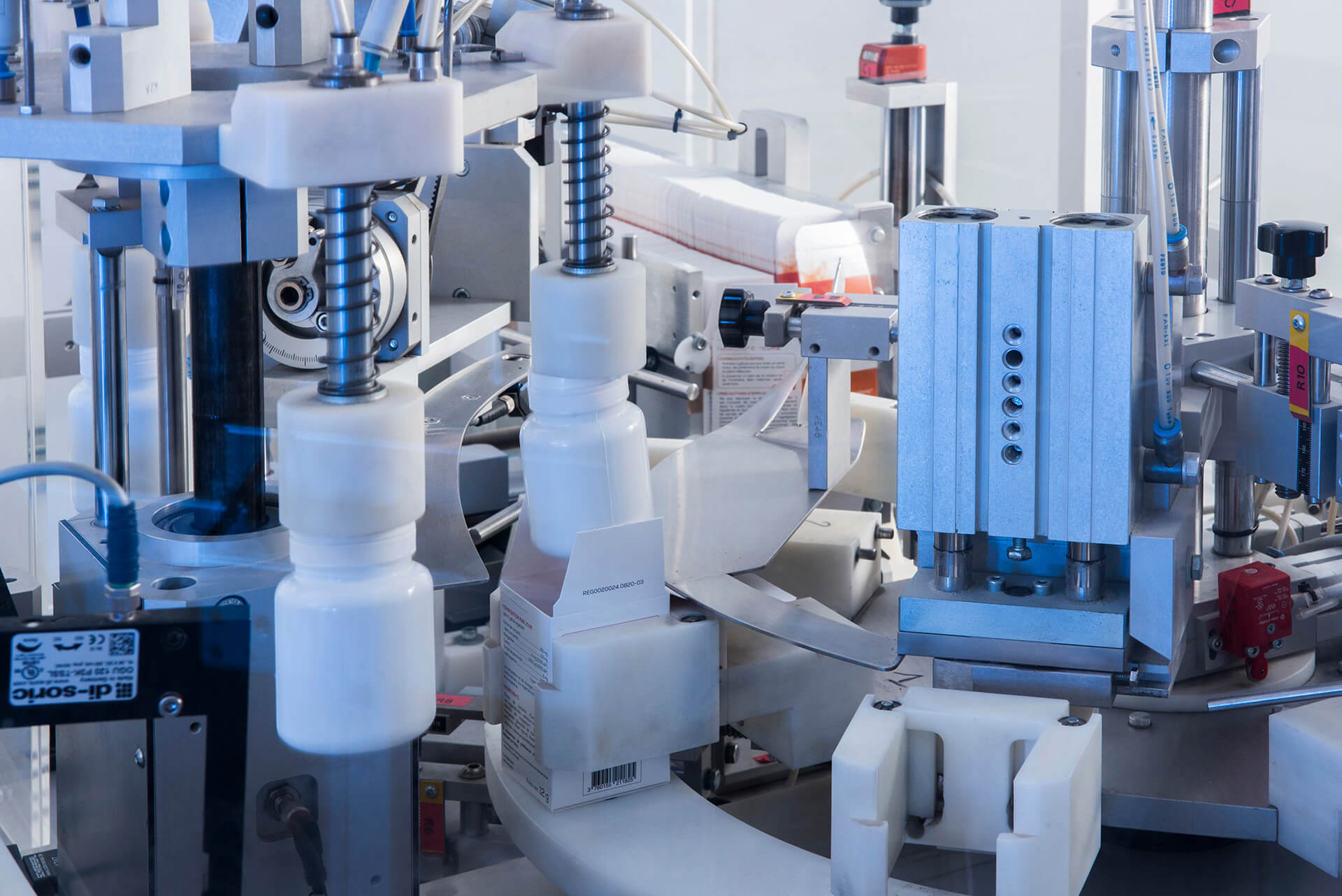

Counting machines for filling bottles and tubes

3 counting machines – 1 tube filler

The counting machines with a rate of 1,200 bottles/hour are equipped with in-line capping/screwing machines, induction sealing, labellers, sleevers and cartoners with insertion of leaflets.

Automatic cartoners

5 cartoners

The packaging of bottles and blisters is automatic; a counting line is equipped with a multi-product cartoner.

Jar-filling machine

1 jar-filling machine

A powder dispenser can fill jars with a capacity of 100 g to 500 g in small and medium series.

Each site has a laboratory for carrying out feasibility and aromatisation tests and can carry out pilot batches and stability studies.

Our large production capacity is flexible and means we can provide an offer adapted to the manufacture of your food supplements with optimised deadlines.